Ku-metallurgy, kokubili ukushisa ngokweqile nokushiswa ngokweqile amagama avamile ahlobene nokwelashwa okushisayo kwezinsimbi, ikakhulukazi ezinqubweni ezifana nokufoja, ukuphonsa, nokwelashwa kokushisa. Nakuba zivame ukudideka, lezi zimo zibhekisela emazingeni ahlukene okulimala kokushisa futhi zinemiphumela ehlukile ezinsimbi. Lesi sihloko sinikeza umbono omfishane wokushisisa ngokweqile nokushiswa ngokweqile, okulandelwa ukuhlola komehluko wabo oyinhloko.

Ukushisa ngokweqile:Ukushisa ngokweqile kubhekisela esimweni lapho insimbi ishiswa ngaphezu kwezinga lokushisa elinconywayo, okuholela esakhiweni sokusanhlamvu esimahhadla. Ku-carbon steel (kokubili i-hypoeutectoid ne-hypereutectoid), ukushisa ngokweqile kuvame ukubonakala ngokwakhiwa kwezakhiwo ze-Widmanstätten. Ezinsimbi zamathuluzi nezinsimbi ze-alloy ephezulu, ukushisa ngokweqile kubonakala njengomumo we-angular we-primary carbides. Kwezinye izinsimbi ze-alloy, ukushisa ngokweqile kungase kubangele ukuna kwezinto eduze kwemingcele yokusanhlamvu. Okunye okubalulekile okukhathazayo ngokushisa ngokweqile ukuthi izinhlamvu eziwumphumela ezimahhadla zingafaka engcupheni izakhiwo zensimbi, zenze i-ductile encane futhi ibe brittle. Kodwa-ke, ezimweni eziningi, umonakalo obangelwa ukushisa ngokweqile ungancishiswa noma uhlehliswe ngokwelashwa okufanele kokushisa.

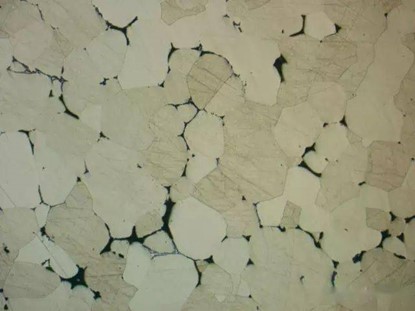

Ukushiswa ngokweqile:Ukushiswa ngokweqile kuyisimo esibi kakhulu uma kuqhathaniswa nokushisa ngokweqile. Kwenzeka lapho insimbi ichayeka emazingeni okushisa angaphezu kwephuzu layo lokuncibilika, okubangela ukuthi impahla yonakale ngendlela engenakulungiseka. Ezinsimbi ezishiswe kakhulu, imifantu ingakheka ngokucindezeleka okuncane ngesikhathi sokuguqulwa. Isibonelo, lapho insimbi eshisiwe ishaywa ngesikhathi sokucasula, iphuka kalula, futhi ngesikhathi sokwelula, imifantu eguquguqukayo ingase ibonakale. Izindawo ezishiswe ngokweqile zihlukaniswa ngezinhlamvu ezimahhadlahhadla ngokwedlulele, futhi izindawo eziphukile ngokuvamile zibonisa umbala ompunga-oluhlaza okwesibhakabhaka okhanyayo. Kuma-alloys e-aluminium, ukushisa ngokweqile kubangela ukuba indawo engaphezulu ibe mnyama, ngokuvamile yakhe umbala omnyama noma omnyama ompunga ngokubukeka okunamabhamuza, okumakiwe. Ukukhulisa okuphezulu kuveza ukuthi ukushisa ngokweqile kuvame ukuhlotshaniswa ne-oxidation kanye nokuncibilika kwemingcele yokusanhlamvu. Ezimweni ezimbi kakhulu, uketshezi lungenzeka emingceleni yokusanhlamvu, okubangele ukuthi impahla yonakale ngendlela engenakulungiseka.

Umehluko Obalulekile:Umehluko oyinhloko phakathi kokushisisa ngokweqile nokushiswa ngokweqile usebukhulwini nokuhlala unomphela komonakalo. Ukushisa ngokweqile kubangela ukuhwalala okusanhlamvu, kodwa insimbi ngokuvamile ingabuyiselwa esimweni sayo sasekuqaleni ngezindlela ezifanele zokwelashwa kokushisa. Umonakalo ngokuvamile ukhawulelwe ezinguqukweni ze-microstructure futhi awuholeli ekuhlulekeni kwenhlekelele ngokushesha ngaphandle uma impahla ingaphansi kwengcindezi enkulu.

Ngakolunye uhlangothi, ukushiswa ngokweqile kumelela isimo esibucayi kakhulu lapho okubalulekile kwenzeka khona umonakalo ongenakulungiseka. Ukuncibilika noma ukucwiliswa kwemingcele yezinhlamvu kusho ukuthi isakhiwo sangaphakathi sensimbi sisengozini ngendlela engenakulungiseka. Ukushiswa ngokweqile kubangela ukonakala kanye nokuqhekeka, futhi alikho inani lokwelashwa kokushisa okulandelayo elingabuyisela izakhiwo zemishini.

Kafushane, ukushisa ngokweqile kanye nokushiswa ngokweqile kokubili kuhlobene nokushisisa ngokweqile, kodwa kuyahluka ngomthelela wazo ezinsimbi. Ukushisa ngokweqile kuvame ukuhlehliswa, kuyilapho ukushisa ngokweqile kubangela umonakalo ongalungiseki, okuholela ekulahlekelweni okukhulu kobuqotho bezinto ezibonakalayo. Ukuqonda lo mehluko kubalulekile ekuqinisekiseni ukuthi ukulawulwa okufanele kwezinga lokushisa kuyagcinwa phakathi nezinqubo ze-metallurgical, ukuvimbela ukwehluleka kwempahla nokuqinisekisa ubude besikhathi sezingxenye zensimbi.

Isikhathi sokuthumela: Oct-08-2024