Ukusebenza kwe-forging kubalulekile ezinhlelweni ezihlukene zezimboni, kusukela ezingxenyeni zezimoto kuya ezingxenyeni ze-aerospace. Ukwengezwa kwama-elementi e-alloy ahlukahlukene kungaba nomthelela omkhulu kuzakhiwo zezinto ezifojiwe, kuthuthukise amandla azo, ukuqina, nokumelana nezinto zemvelo. Lesi sihloko sihlola ezinye zezinto ezibalulekile ze-alloying nokuthi zithinta kanjani ukusebenza kwe-forging.

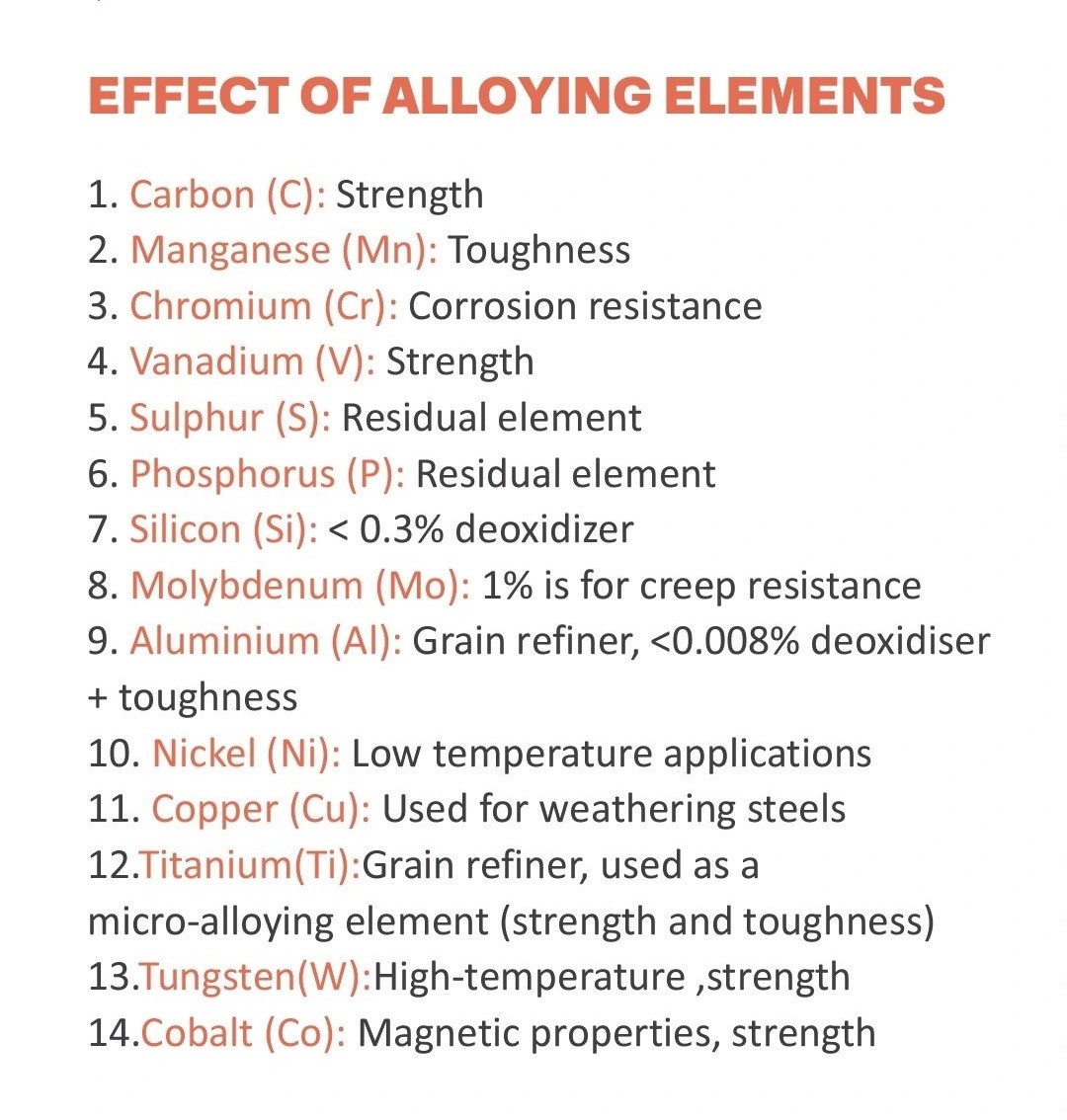

Izakhi Eziyisihluthulelo Zengxubevange kanye Nemiphumela Yazo

Ikhabhoni (C):

I-Carbon ingenye yezakhi ezibaluleke kakhulu ze-alloying ensimbi. Ithonya ngokuqondile ubulukhuni namandla wento. Okuqukethwe kwekhabhoni ephezulu kukhulisa ubulukhuni namandla okuqina kokufoja, kuyenza ifaneleke izinhlelo zokusebenza ezidinga ukumelana nokugqokwa okuphezulu, njengamathuluzi okusika nezingxenye zezimoto. Kodwa-ke, ikhabhoni eningi ingenza izinto zibe brittle, kunciphise ukumelana nomthelela wayo.

I-Chromium (Cr):

I-Chromium yaziwa ngamandla ayo okuthuthukisa ukumelana nokugqwala nobulukhuni. Yakha ungqimba olwenziwayo lwe-chromium oxide ngaphezulu, ivikela i-forging kusuka ku-oxidation kanye nokugqwala. Lokhu kwenza izinsimbi ezinengxube ye-chromium zilungele ukusetshenziswa ezindaweni ezinokhahlo, njengezimboni zasolwandle namakhemikhali. Ukwengeza, i-chromium ithuthukisa ukuqina kwensimbi, ukuyivumela ukuthi ifinyelele amandla aphezulu kanye nokuqina ngemva kokwelashwa kokushisa.

I-Nickel (Ni):

I-nickel yengezwa kuma-forgings ukuze kuthuthukiswe ukuqina nokuqina kwawo, ikakhulukazi emazingeni okushisa aphansi. Iphinde ithuthukise ukumelana kwempahla ukugqwala kanye ne-oxidation. Izinsimbi ezine-nickel-alloyed zivame ukusetshenziswa ezimbonini ze-aerospace kanye zikawoyela negesi, lapho kudingeka khona kokubili amandla aphezulu nokumelana nezindawo ezinokhahlo. Ukuba khona kwe-nickel kuphinde kuzinze isigaba se-austenitic, okwenza insimbi ingabi-magnetic futhi ithuthukise ukusebenza kwayo.

Imiphumela Ehlanganisiwe Nezicelo Zezimboni

Inhlanganisela yalezi nezinye izakhi ze-alloying, njenge-molybdenum (Mo), i-vanadium (V), ne-manganese (Mn), ingakhiqiza izinto ezinezici ezilungiselelwe ukusetshenziswa okuthile. Isibonelo, i-molybdenum inyusa amandla okushisa aphezulu kanye nokumelana nokukhasa kwensimbi, iyenze ifanele ama-turbine blades nemikhumbi yokucindezela. I-Vanadium icwenga ukwakheka okusanhlamvu, ithuthukise amandla kanye nokuqina kokubumba. I-Manganese isebenza njenge-deoxidizer futhi ithuthukisa ukuqina namandla aqinile wento.

Embonini yezimoto, ama-forging anenhlanganisela elinganiselayo ye-carbon, i-chromium, ne-manganese asetshenziselwa ukukhiqiza izinto ezinamandla kakhulu, ezingagugi njengama-crankshaft namagiya. Emkhakheni we-aerospace, ama-alloys e-nickel ne-titanium abalulekile ekukhiqizeni izingxenye ezingasindi kodwa eziqinile ezikwazi ukumelana nezinga lokushisa elidlulele kanye nengcindezi.

Isiphetho

Ukusebenza kwe-forging kuthonywa kakhulu ukwengezwa kwama-elementi e-alloying, ngayinye inikela ngezici ezithile ezithuthukisa ukusebenza okuphelele kwezinto. Ukuqonda indima yezinto ezifana nekhabhoni, i-chromium, ne-nickel kusiza izazi ze-metallurgist nonjiniyela badizayine ama-forging ahlangabezana nezidingo ezinzima zezinhlelo zokusebenza ezihlukene zezimboni. Ngokukhetha ngokucophelela nokuhlanganisa lezi zakhi, abakhiqizi bangakhiqiza izinto zokwakha zekhwalithi ephezulu ezinamandla aphezulu, ukuqina, nokumelana nezici zemvelo, okuqinisekisa ukwethembeka nokuphila isikhathi eside ezinhlelweni zabo zokusebenza.

Isikhathi sokuthumela: Jul-30-2024