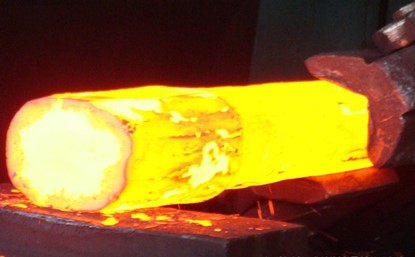

Enqubweni yokuqamba, ukucasula kubhekisela ekuguquguqukeni kwesiqeshana sokusebenza ukuze kwandiswe ububanzi baso ngokucindezela ubude baso. Ipharamitha ebalulekile ekucasuleni yi-isilinganiso sobude ukuya kobubanzi (isilinganiso se-H/D), edlala indima ebalulekile ekunqumeni ikhwalithi yomkhiqizo wokugcina kanye nokuba nokwenzeka kwenqubo. Isilinganiso sobude ukuya kobubanzi sisetshenziselwa ukuqinisekisa ukuthi ukuwohloka kuhlala kulawulwa futhi kufana, ukuvimbela izinkinga ezifana nokubopha, ukuqhekeka, noma ukwehluleka kwezinto.

Iyini i-Height-to-Diameter Ratio?

Isilinganiso sobude nobubanzi (isilinganiso se-H/D) isilinganiso phakathi kobude (noma ubude) besiqephu sokusebenza kanye nobubanzi baso ngaphambi kokufoja. Lesi silinganiso sisiza ukuchaza ukuthi kungakanani okubalulekile okungakhubazeka ngenqubo yokucasula. Ngokuvamile, uma isilinganiso siba sincane, inqubo yokucasula iba nokwenzeka nakakhulu ngoba izinto ezimfushane, eziwugqinsi zingamelana namandla amakhulu okucindezela ngaphandle kokugoqa noma ukukhula kokukhubazeka.

Isibonelo, isilinganiso esiphansi se-H/D, esifana no-1.5:1 noma ngaphansi, sibonisa isiqeshana somsebenzi esiqinile, esingamelana nemithwalo ephezulu ecindezelayo ngaphandle kwezingozi ezinkulu zokungaqini. Ngakolunye uhlangothi, isilinganiso esiphezulu, esifana ne-3: 1 noma ngaphezulu, singadinga ukucatshangelwa ngokucophelela, njengoba ucezu lomsebenzi luba sengozini yokukhubazeka.

Ungasithola Kanjani Isilinganiso Esifanelekile Se-H/D?

Isilinganiso se-H/D esifanelekile sincike ezintweni ezimbalwa, okuhlanganisa izakhiwo zezinto ezibonakalayo, izinga lokushisa lezinto ngesikhathi sokufojwa, kanye nezinga lokuwohloka elidingekayo. Nazi izinyathelo eziyinhloko zokunquma isilinganiso esilungile se-H/D sokucasula:

- Izinto ezibonakalayo: Izinto ezihlukile zibonisa amandla ahlukene okucindezela kanye ne-ductility. Izinto ezithambile, njenge-aluminium, zingabekezelela ukuwohloka okwengeziwe ngaphandle kokuqhekeka, kuyilapho izinto eziqinile njengensimbi enekhabhoni ephezulu zingadinga isilinganiso esiphansi se-H/D ukugwema ingcindezi eyeqile. Ukucindezelwa kokugeleza kwezinto, okungukuthi, ukucindezeleka okudingekayo ukuqhubeka nokuguqula izinto ezibonakalayo ngepulasitiki, kufanele kucatshangelwe.

- Izimo Zezinga lokushisa: I-Hot Forging yenziwa ngokujwayelekile emazingeni okushisa athuthukisa i-ductility yezinto futhi anciphise amandla adingekayo. Amazinga okushisa aphezulu avumela ukuwohloka okukhulu, okuvumela isilinganiso esikhulu sobude nobubanzi. Ngokwenza okubandayo, isilinganiso se-H/D kufanele sigcinwe sincane ngenxa yokwanda kwengozi yokuqina nokuqhekeka komsebenzi.

- Izinga le-Deformation: Inani lokuguqulwa elidingekayo lingesinye isici esibalulekile. Uma kudingeka ukuncipha okuphawulekayo kobude, ukuqala ngesilinganiso esiphansi se-H/D kunenzuzo ukuqinisekisa ukuthi ucezu lokusebenza lungakwazi ukucindezelwa okudingekile ngaphandle kokukhubazeka.

- Ukugwema Amaphutha: Uma kunqunywa isilinganiso se-H/D, kubalulekile ukugwema iziphambeko ezifana nokubopha, okwenzeka lapho okubalulekile kugoqeka noma kushwabana phakathi nokucindezelwa. Ukuze ugweme ukugoqana, umthetho ojwayelekile wesithupha uwukusebenzisa isilinganiso sokuqala se-H/D esingaphansi kuka-2:1 ukuze uthole ukucasuka okuvamile. Ukwengeza, i-lubrication kanye nomklamo ofanele wokufa kubalulekile ukuze unciphise ukungqubuzana nokuqinisekisa ukuguquguquka okufanayo.

Isibonelo Esisebenzayo

Cabanga ngendaba yokucasula i-cylindrical billet yensimbi. Uma ukuphakama kokuqala kwe-billet kungu-200 mm futhi ububanzi bungu-100 mm, isilinganiso se-H/D singaba ngu-2:1. Uma impahla ithambile uma kuqhathaniswa, futhi kusetshenziswa i-hot forging, lesi silinganiso singamukeleka. Kodwa-ke, uma kusetshenziswa ukubumba okubandayo, ukunciphisa ubude ukuze kwehliswe isilinganiso se-H/D kungase kudingeke ukuze ugweme ukugoqa noma ukuqhekeka phakathi nenqubo yokucasula.

Isiphetho

Isilinganiso sobude ukuya kobubanzi ekucasuleni siyisici esiyisisekelo sokuqamba esinquma impumelelo yenqubo. Ngokuhlola ngokucophelela izakhiwo zezinto ezibonakalayo, izimfuneko zokushisa, kanye nokuguqulwa, isilinganiso esifanele singasungulwa, siqinisekise ukukhiqizwa kwezingxenye ezimboziwe zekhwalithi ephezulu, ezingenasici.

Isikhathi sokuthumela: Sep-18-2024