Okuqukethwe kwekhabhoni ensimbi kungenye yezinto ezibaluleke kakhulu ezithonya ukushisela kwezinto zokwakha. Insimbi, inhlanganisela yensimbi nekhabhoni, ingaba namazinga ahlukene ekhabhoni, athinta ngqo izici zayo zemishini, okuhlanganisa amandla, ubulukhuni, kanye ne-ductility. Kuma-forging ashiselwe, ukuqonda ubudlelwano phakathi kokuqukethwe kwekhabhoni nokusebenza kokushisela kubalulekile ukuze kuqinisekiswe ubuqotho nekhwalithi yamalunga ashiselwe.

Izinsimbi ezinekhabhoni ephansi, ngokuvamile eziqukethe ikhabhoni engaphansi kuka-0.30%, ziyizinto ezishiselelwa kakhulu. Lezi zinsimbi zibonisa i-ductility enhle kanye nokusebenziseka kalula, okuzenza zilungele uhla olubanzi lwezinhlelo zokushisela. Okuqukethwe kwekhabhoni ephansi kunciphisa ubungozi bokuqhekeka endaweni ethinteke ukushisa (HAZ) ngesikhathi nangemuva kokushisela. Lokhu kungenxa yokuthi amazinga ekhabhoni aphansi abangela ukuqina okuphansi, okusho ukuthi impahla mancane amathuba okuthi yenze ama-microstructures ama-brittle njenge-martensite, engaba yinkinga ezindaweni ezishiselwe. Ngakho-ke, ama-forging anokuqukethwe kwekhabhoni ephansi avame ukuba nezinkinga ezimbalwa ezihlobene nokuqhekeka noma ukuhlanekezela ngesikhathi sezinqubo zokushisela.

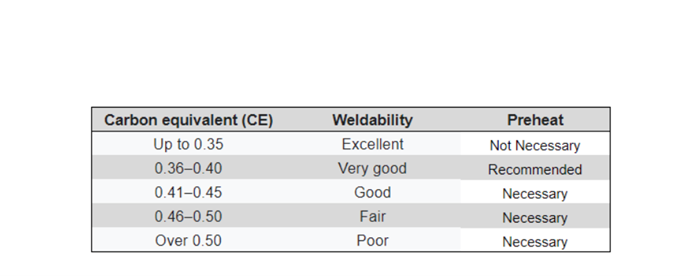

Ngokuphambene, njengoba okuqukethwe kwekhabhoni kwanda, ukushisela kwensimbi kuncipha. Izinsimbi ezinekhabhoni emaphakathi, ezinokuqukethwe kwekhabhoni okusukela phakathi kuka-0.30% no-0.60%, zinikeza amandla aphakeme nobulukhuni uma kuqhathaniswa nezinsimbi ezinekhabhoni ephansi kodwa eza nezingozi ezengeziwe ngesikhathi sokushisela. Okuqukethwe kwekhabhoni ephezulu kuholela ekuqineni okukhulu, okwandisa amathuba okwakhiwa kwezakhiwo ze-martensitic ku-HAZ. Lawa ma-microstructures aqinile futhi ama-brittle, aphakamisa amathuba okuqhekeka, ikakhulukazi ngaphansi kwengcindezi noma umthelela. Ukunakekelwa okukhethekile, okufana nokushisa kwangaphambili kanye nokwelashwa kokushisa kwangemuva kwe-weld, kuvame ukudingeka lapho kushiselwa ama-forging ensimbi enekhabhoni ephakathi ukuze kunqandwe lezi zinkinga.

Izinsimbi ezinekhabhoni ephezulu, eziqukethe i-carbon engaphezu kuka-0.60%, ziletha izinselelo ezinkulu zokushisela. Okuqukethwe kwekhabhoni ephezulu kukhulisa kakhulu ubulukhuni bensimbi kanye nokuqina kwayo, okuyenza ithandeke kakhulu ekuqhekekeni ngesikhathi senqubo yokushisela. Kwezinye izimo, izinsimbi ezinekhabhoni ephezulu zingadinga amasu okushisela akhethekile noma zingakufanelekeli nhlobo ukushisela ngaphandle kokuguqulwa okunamandla kule nqubo. Ukushisa kuqala, ukulawulwa kwezinga lokushisa phakathi, kanye nokwelashwa kokushisa kwangemva kokushisela kubalulekile ukuze kugwenywe ukwehluleka okuqinile ekufakeni kwensimbi enekhabhoni ephezulu.

Kafushane, okuqukethwe kwekhabhoni yensimbi kudlala indima ebalulekile ekunqumeni impumelelo yokushisela ezingxenyeni ezibunjiwe. Izinsimbi ezinekhabhoni ephansi yizona ezishisela kakhulu, kuyilapho izinsimbi ezinekhabhoni ephakathi nendawo neziphezulu zidinga ukulawulwa ngokucophelela kwemingcele yokushisela ukuze kuvinjelwe amaphutha njengokuqhekeka. Ukuqonda okuqukethwe kwekhabhoni kanye nokukhetha izinqubo ezifanele zokushisela kubalulekile ukuze kuqinisekiswe ukuqina nokusebenza kwama-welded forgings kuzinhlelo zokusebenza ezihlukene zezimboni.

Isikhathi sokuthumela: Oct-16-2024